How to make colored acrylic sheets?

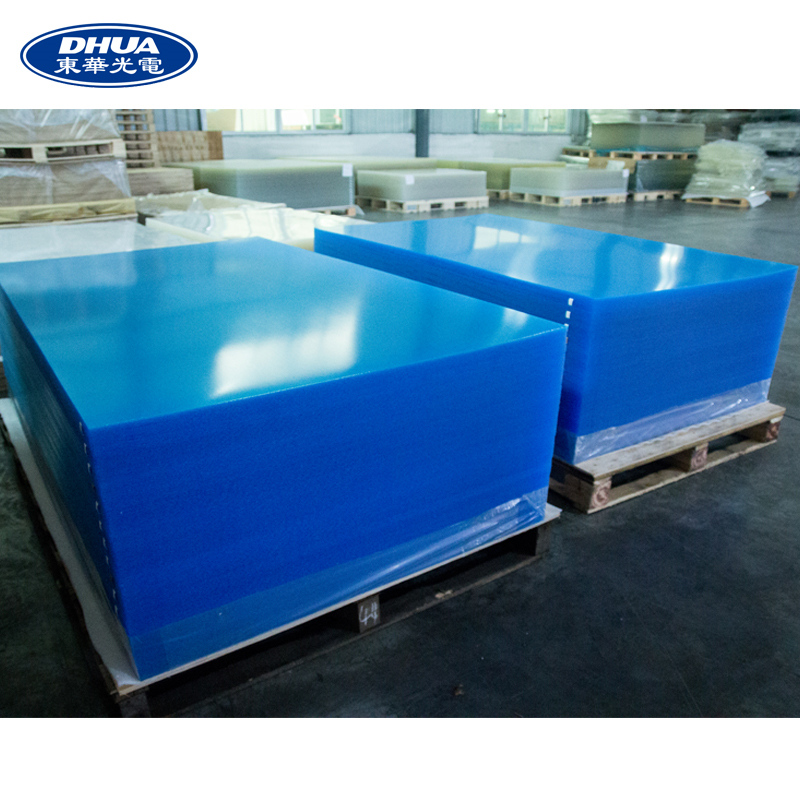

Acrylic sheets are used in a wide variety of industries and applications for their versatility, durability, and visual appeal. They come in a variety of colors and are suitable for countless projects such as signage, furniture, displays, and artistic creations. In this article, we'll explore the process of making colored acrylic sheets and delve into the factors that affect their price.

Acrylic sheets are usually manufactured using a process called extrusion. This involves using a machine called an extruder to melt acrylic pellets, which are then forced through a die to form a continuous sheet. During this process, colored pigments can be added to the acrylic resin to obtain the desired color.

Color pigments used in acrylic sheets are usually in the form of powder or liquid dispersion. These pigments are composed of various organic and inorganic compounds that produce different shades and shades. Pigment selection depends on the desired color and desired properties of the final product.

To make colored acrylic sheets, pigments are mixed with virgin acrylic resin, then melted in an extruder. The ratio of pigment to resin can vary depending on the intensity of color desired. Once the pigment is thoroughly mixed with the resin, the mixture is heated and forced through a mold to form a continuous sheet of colored acrylic.

One of the factors that affect the color of an acrylic sheet is its thickness. Thicker paper may appear more vibrant and saturated than thinner paper because the color pigments are dispersed over a greater volume. In addition, the transparency of the acrylic sheet will also affect its color. Compared with translucent or opaque sheets, transparent acrylic sheets allow more light to pass through, resulting in different visual effects.

In terms of pricing, the price of colored acrylic sheets depends on a variety of factors. First, the cost of raw materials including acrylics and color pigments will affect the price of the board. Higher quality pigments or specialty colors may result in higher costs. Additionally, the manufacturing process, including extrusion and any subsequent treatments such as polishing or coating, also affects price.

Also, the demand and availability of a particular color can affect its price. Popular or commonly used colors may be less expensive due to their wide availability. Conversely, special or custom colors can be more expensive because of the extra effort required to produce them.

It's worth noting that while colored acrylic sheets are widely available in the market, some individuals or businesses may prefer to create their own custom colors. This can be achieved by purchasing a sheet of clear acrylic and applying a colored film or coating. These films or coatings allow greater flexibility and customization in achieving specific colors or effects.

-

frank.huang61

-

+86 13725766861

Post time: Jul-29-2023