Acrylic Mirror vs Polycarbonate Mirror

Transparent Acrylic sheet, Polycarbonate sheet, PS sheet, PETG sheet looks very similar, in the same color, same thickness, it is difficult for non-professionals to distinguish between them. In the last article, we introduced the difference between acrylic and PETG , today we continue with information about acrylic mirror and Polycarbonate mirror for you.

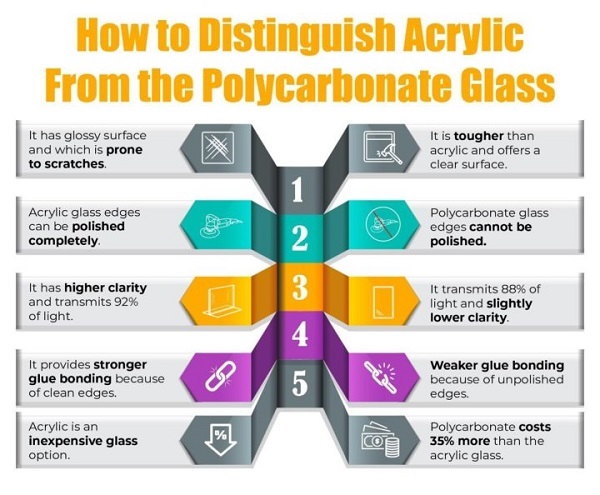

| Acrylic | Polycarbonate (PC) | |

| Recognition | Acrylic has a glass-like gloss surface and scuffs the surface lightly. It is more transparent and can be softened to form any kind of shape.

Acrylic has perfectly glass clear edges which can be polished completely clear.

If burn it with fire, the flame of acrylic is clear when burning, no smoke, no bubbles, no squeaking sound, no silk when extinguishing fire.

|

If the surface is tough, stable, clear, and lighter in weight than acrylic sheets, it is polycarbonate.

The edges of the Polycarbonate sheet cannot be polished.

Burning with fire, polycarbonate is basically unable to burn, flame retardant, and will emit some black smoke. |

| Clarity | Acrylic has a better clarity with 92% light transmittance | Polycarbonate slightly lower clarity with 88% light transmittance |

| Strength | Being about 17 times more impact resistant than glass | Polycarbonate comes out on top. Significantly stronger, with 250 times more impact resistance than glass and 30 times impact strength than acrylic. |

| Durability | They’re both fairly durable. But acrylic is a bit more rigid than polycarbonate at room temperature, so it is more likely to chip or crack when struck with a sharp or heavy object. However, acrylic has a higher pencil hardness than polycarbonate, and is more resistant to scratches. | Owing to the unique features like a low level of flammability, durability, polycarbonate can be drilled without cracking chipping. |

| Production Issues | Acrylic can be polished if there’s a very small imperfection present.Acrylic is more rigid, so it does need to be heated in order to form it into various shapes. However, heat does not damage or break down the material at all, so it is a great option for thermoforming.

Acrylic can also be formed without a pre-drying process, which is required in polycarbonate forming. |

Polycarbonate is not able to be polished in order to restore clarity.Polycarbonate tends to be fairly flexible at room temperature, which is one of the qualities that makes it so impact resistant. so it can be shaped without applying extra heat (a process commonly referred to as cold forming). It is known for being fairly easy to machine and cut. |

| Applications | Acrylic is usually preferred in instances where a very clear and lightweight material is needed. It can also be the optimal choice in instances where a very specific size and shape is required, since it’s easy to form without impacting the visibility.Acrylic sheeting is popular in these applications:

·Retail display cases ·Light fixtures and diffusing panels ·Transparent shelves and holders for brochures or print materials ·Indoor and outdoor signage ·Craft of DIY projects ·Skylights or exterior windows that are exposed to excessive UV rays

|

Polycarbonate is often preferred in instances where extreme strength is needed, or in instances where the material may be exposed to high heat (or flame resistance), since acrylic can become too flexible in that environment.More specifically, polycarbonate sheeting is popular in the following instances:

·Bullet resistant “glass” windows and doors ·Windshields and operator protection in various vehicles ·Clear visors in protective sporting gear ·Technology cases ·Machinery guards ·Protective guards in industrial settings where heat or chemicals are present ·UV grades for signage and outdoor use

|

| Cost | Acrylic plastic is less expensive, more affordable than Polycarbonate plastic. The price of acrylic depends on the thickness of the material. | Polycarbonate has higher cost, as much as 35% more expensive (depending on the grade). |

Please follow our social media and website to learn more information about difference of other plastics.

Post time: Jul-25-2022