Clear Plexiglas Mirror: Find Your Ideal Size

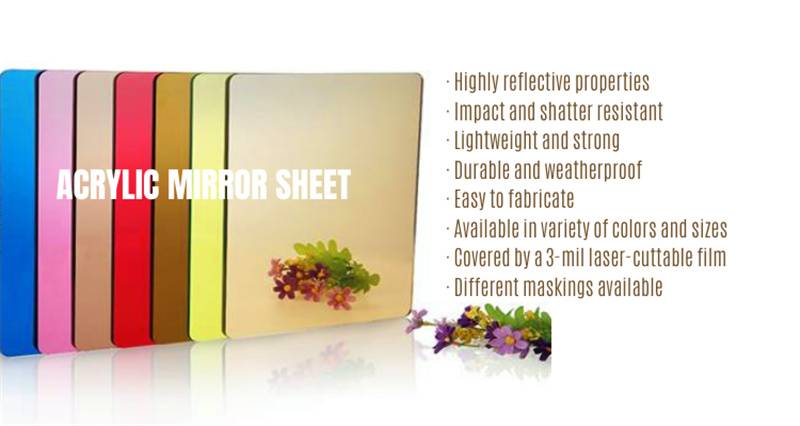

Clear plexiglass mirrors offer several advantages including:

Lightweight: Plexiglass mirrors are lighter than glass mirrors, making them easier to handle and install.

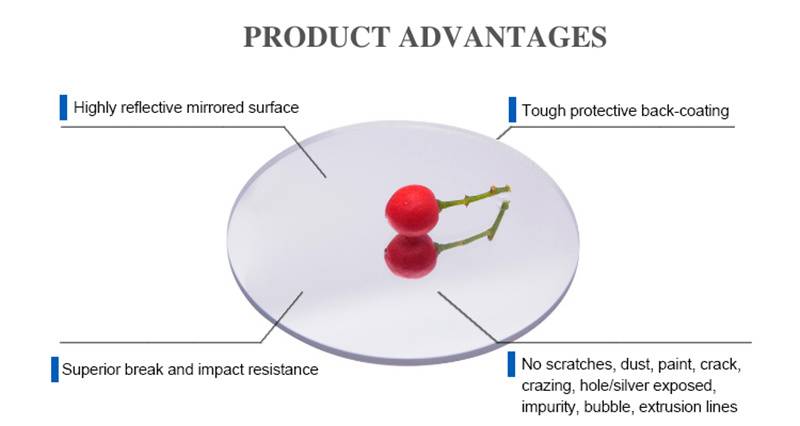

Shatter-resistant: Plexiglass mirrors are more durable and less likely to shatter compared to traditional glass mirrors, making them a safer option, especially in environments where safety is a concern.

Impact resistance: Due to their acrylic composition, plexiglass mirrors are more impact-resistant than glass mirrors, making them suitable for use in high-traffic areas or where there is a risk of breakage.

Weather resistance: Plexiglass mirrors are better able to withstand outdoor elements such as rain, sunlight, and temperature changes, making them suitable for outdoor applications.

Versatility: Plexiglass mirrors can be easily cut and shaped to fit various design needs, and they are available in a variety of thicknesses and sizes.

Transparency: Clear plexiglass mirrors provide excellent optical clarity and can be polished to a high shine, making them an attractive alternative to traditional glass mirrors.

| Product name | Clear acrylic plexiglass mirror sheet |

| Material | Virgin PMMA material |

| Surface Finish | Glossy |

| Color | Clear, silver |

| Size | 1220*2440 mm, 1220*1830 mm, custom cut-to-size |

| Thickness | 1-6 mm |

| Density | 1.2 g/cm3 |

| Masking | Film or kraft paper |

| Application | Decoration, advertising, display, crafts, cosmetics, security, etc. |

| MOQ | 50 sheets |

| Sample time | 1-3 days |

| Delivery time | 10-20 days after getting deposit |

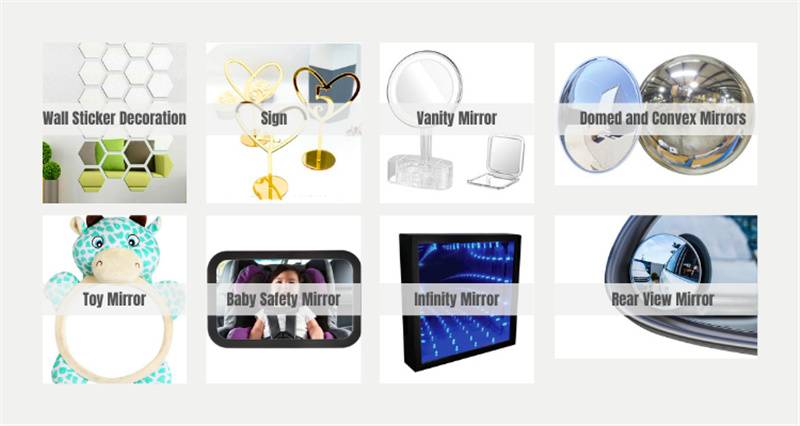

Application

Our acrylic mirror sheets are suitable for a wide range of applications. There are many common uses, with the most popular being Point of sale/Point of purchase, retail display, signage, security, cosmetics, marine, and automotive projects, as well as decorative furniture and cabinet making, display cases, POP/retail/store fixtures, decorative and interior design and DIY projects applications.

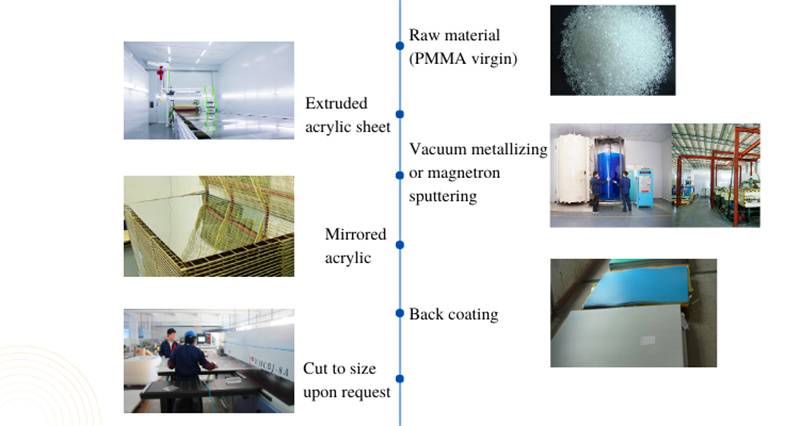

Production Process

Dhua Acrylic Mirror Sheet is made with extruded acrylic sheet. Mirrorizing is done by the process of vacuum metallizing with aluminum being the primary metal evaporated.

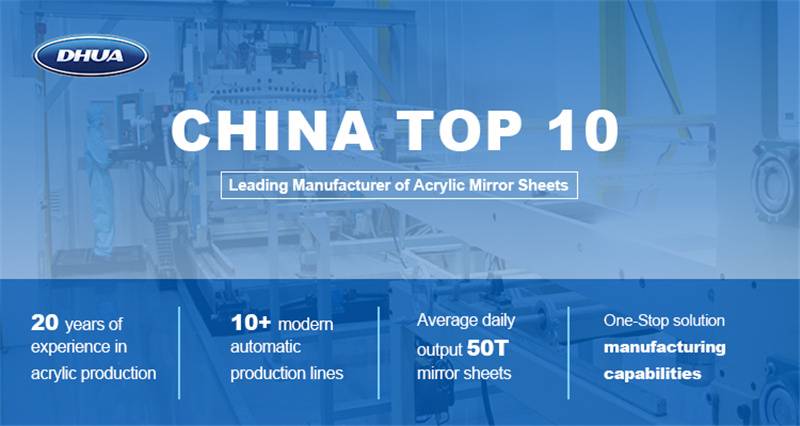

We Are a Professional Manufacturer